Basetube Instrument Mounts

Share

Winter hits us hard here in Canada - so much so that we can't really fly, especially here in the flats where we have zero ridges to take advantage of. This turns our focus here at Instinct to our "winter projects" - ideas that are stuck in our brains all flying season as we have no time to work on them. Quite often these projects take many winters to come to fruition

Our next winter project that is coming to completion is our instrument mounts. We have been working with Jo to make some awesome carbon and fiberglass instrument pods - his first one (for Flymaster pods) is on the market now but we weren't happy with using the industry standard/universal Flytec downtube instrument mount that velcros on. For one, they aren't cool looking (but sure are functional) and two, basetube solutions are much better as it gets our flight computers lower on the control frame as when competition pilots race, their heads are too low to be able to see downtube-mounted-instruments.

We didn't care much for the other basetube mounts out there on the market, some are 3D printed....they don't look all that clean and worry about their longevity in our sometimes harsh environments that our basetubes endure. There are other aluminum or carbon fiber solutions on the market as well but are quite pricey...and of course, we don't make them! :)

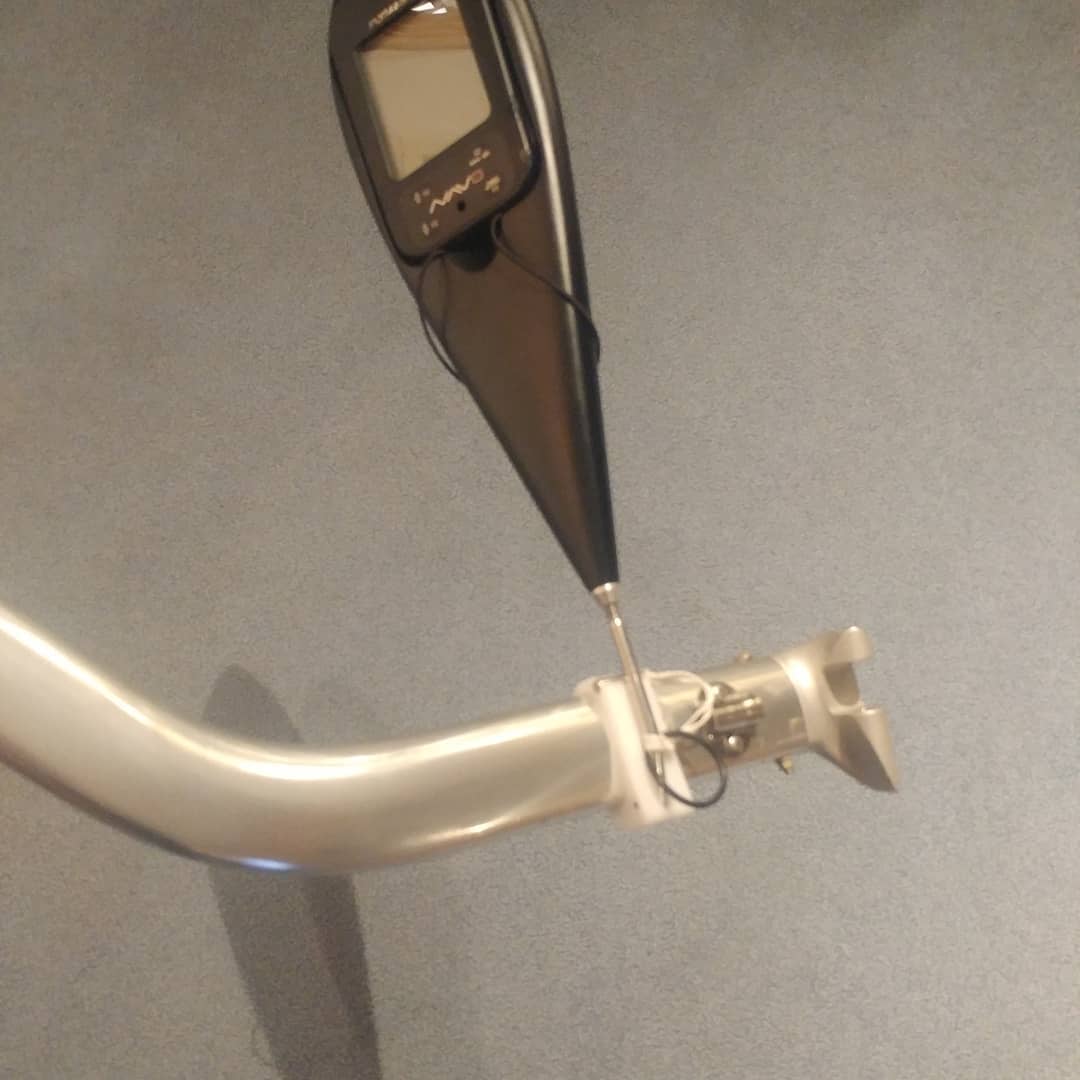

So our own first basetube instrument mount is now ready. Nick made it for the WillsWing aluminum basetube as that is what his glider has but ones for WillsWing and Moyes Carbon basetubes and the Moyes FAST aluminum basetube are in short order as well.

We are still finalizing the design. As you can see in this picture, we went for a "living-hinge" where the stainless rod gets removed allowing the mount to flex for removal. This design is NOT needed for the carbon basetubes as those can be slipped on from the handle portion of the bastube but aluminum basetubes are uniform in the handles so this won't work. But since the engineering-grade nylon we use (UHMW) has 'some' flex to it, we think we can tweek the thickness to get it to snap on the basetube without needing this removable rod at the leading edge of the mount. Besides, all the force of the instrument gets transferred to the trailing edge of the mount and that is well hooked around the trailing edge.

Security of your instruments is of up-most priority of course so we won't compromise on that of course. We are also going to test them while heated up to ensure they don't flex in 40ºC heat. As always though...be sure to lanyard your instruments to your glider just in case.

The mount will have a standard 1/4"-20 threaded rod to go into our Flymaster instrument pod. So as long as your existing instrument pod can accept that, our mount will work with it. If you have an M6 or M8 pod (ie from AltAir), we will be able to accommodate that request....it will just take us a bit of time to fill your order as we likely won't have them in stock.